Greatest threat to manufacturing industry is cyber security, not job security, new research finds

In the midst of rapid global manufacturing change, 74% of senior management across Europe agree that local economies and job prospects will be boosted thanks to technology and urge Europe to shift attention away from job security concerns to address cyber threats, new research from Epson reveals.

When asked, 67% of the European workforce in the manufacturing industry agrees that cyber security poses the greatest threat, rising to 76% of those in management roles. With the manufacturing sector comprising 15% of Europe’s overall GDP3, and contributing over 52 million direct or indirect jobs4, the research reveals a refreshingly positive employment outlook amidst an era of uncertainty in Europe as technologies like robotics edge their way in to today’s large-scale production facilities. In fact, 60% of the current workforce agrees that robots will not be able to replace human ability for flexibility, creativity and reaction and 62% said that manufacturing jobs will evolve with technology, not be replaced by it; supporting Europe’s drive towards a more human-centric business model in manufacturing.

As smart factories and technology becomes more widely adopted, manufacturing, as we know it, will take shape in new ways and ideals. Factories, remotely identifying demand, will offer faster, cheaper and more on-demand production, and 40% of those within manufacturing believe supply chains will become shorter. Furthermore, 57% agree that production facilities will become more localised, offering customised manufacturing that will replace mass global production and provide considerable benefits to business, the environment and society. On top of economic prosperity, 83% of respondents within manufacturing said technology would improve an organisation’s efficiency (the highest across all industries surveyed in Europe) and expressed that their individual roles would become more efficient, more productive, more accurate, more analytical and more creative.

The research pooled insights from 17 global industry experts and put them to more than 7,000 full-time employees from selected sectors across Europe, including 1,500 working in the manufacturing sector, to explore their opinions on how technology could shape the future of their industry and their workplace.

Almost half (47%) of respondents in manufacturing stated that technology will disrupt their role in the future meaning more training and upskilling will be required to reap the benefits technology presents in this space. When asked, 68% said they would retrain if their current role was threatened by new technologies – showing a willingness to embrace technological change – compared to 13% that said they would leave for a new job altogether without training. For those that remain in the industry, it is likely they will see roles shift away from manufacturing operations as they know it and towards technology-related operations, particularly in coding and cyber security.

These technologies may be widely viewed as the drivers of innovation that will catapult our industries into the future; however, in addition to concerns around cyber security, 55% of respondents agree that companies may struggle to keep up with regulatory requirements, for example when integrating robots into manufacturing infrastructure.

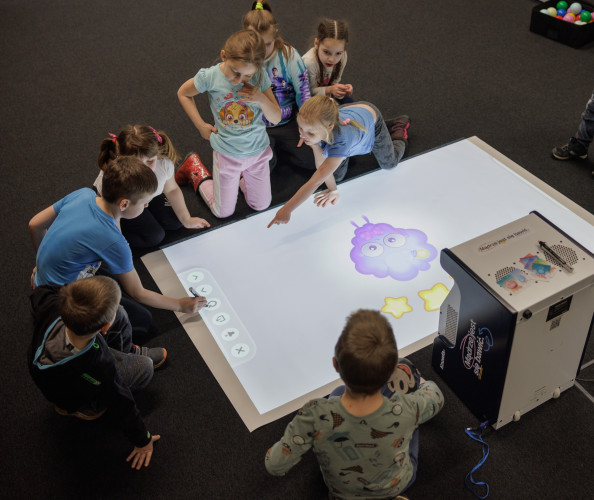

"Our work and workplaces are becoming more interconnected, and technology is transforming our factories, offices, homes, hospitals and schools – the environments which shape our lives. Manufacturing and the development of industrial robots has been at the heart of what Epson does as a company since its beginning. While manufacturing is being redefined by technologies like robots and 3D printers, people will remain at its core and integral to any strategy for businesses looking to retain a competitive edge," says Epson Global President, Mr. Minoru Usui.

"As a company, Epson is dedicated to facilitating a positive technological shift by developing solutions that will make workforces more efficient and more productive. Our core technologies – wearables, robotics, visual imaging products and printing technologies – are poised to deliver new possibilities in manufacturing and beyond, with the vision of the future in mind. We are already gaining new insights based on more information, heightened creativity and increased efficiency, and there are still improvements to come," adds Mr. Usui.

About the study

The two-phase research project was conducted by FTI Consulting. Phase one consisted of qualitative telephone interviews with 17 global futurists and European experts from various sectors from 22nd September-19th October 2016 to gain insights and develop hypotheses on the future of the workplace and the changing roles of the workforce leading up to 2025. Phase two consisted of a quantitative online survey conducted by FTI Consulting’s Strategy Consulting & Research team from 2nd-13th December 2016. Respondents included full-time employees across five major sectors (corporate, manufacturing, education, healthcare and retail) in workplaces across the United Kingdom, France, Germany, Italy and Spain in their local languages.

A total of n=7,016 full-time employees completed the survey. The breakdown of the respondents who completed the survey in each country are as follows: United Kingdom (1,329), France (1,308), Germany (1,427), Italy (1,526), Spain (1,426). The breakdown of the respondents who completed the survey in each industry sector are as follows: corporate (2,051), manufacturing (1,519), education (1,090), healthcare (1,215), retail (1,139).

The n=7,016 completes yields a 3% +/- margin of error with an industry standard 95% confidence interval. Please note that the standard convention for rounding has been applied and consequently some totals do not add up to 100%.

For further information on the research methodology or FTI Consulting’s market research services: Market.Research@fticonsulting.com

Global futurists and European experts interviewed

- Jonathan Reynolds, Academic Director of the Oxford Institute of Retail Management (OXIRM), Associate Professor in Retail Marketing and Deputy Dean at Said Business School

- Howard Saunders, Retail Futurist, Twenty Second & Fifth

- Dave White, Head of Technology Enhanced Learning, University of the Arts London

- Russel Stannard, Education Technologist and founder of www.teachertrainingvideos.com

- Professor Darwin Cadwell, Research Director, Italian Institute of Technology in Genoa and Chair of the IEEE Robotics and Automation Chapter (UKRI)

- Professor Alain Bernard, Research Director, Laboratoire IRCCyN; Vice-President, AFPR; Vice-Chairman, WG5.1 of IFIP; and member of CIRP Council in France

- Clive Hickman, Chief Executive, Manufacturing Technology Centre

- Christopher Barnatt, Futurist, ExplainingTheFuture.com

- Gerd Leonhard, Futurist, The Future Agency

- Ben Hammersley, Journalist, Technologist, Futurist

- Brice Le Blévennec, CEO at Emakina

- Clinton Wingrove, HR Futurist

- Dr. Bertalan Mesko, Futurist, Founder of The Medical Futurist

- Giuliano Noci, Professor

- Richard Webber, Professor

- Dr. Tobias Gantner, Healthcare Futurist, HealthCare Futurists GmbH

- Mariano Corso, Scientific Officer